|

The 3D printer has been collecting dust for over a year and the last few months it has been living in its storage box. One of the reasons I have not used it much is because it hasn't been printing well. It hasn't been printing well because I did not properly assemble the extruder assembly when I upgraded several parts.

Now I had time and motivation to go and resolve this. Time for a game plan. I was fairly confident all the issues where in the extruder assembly. So the plan was to carefully take it apart. Clean all the parts. And assemble it in very specific order so it the extruder is assembled correctly. With the extruder on the Makerbot replicator and possibly other 3D printers on the market you have to be very careful with the disassembly of the extruder head. Some parts you can only loosen when the extruder is warm/hot. For example the nozzle might break off if you try and undo it while cold. This will be a challenge to then repair. So knowing this in advance and trying to mitigate these possible problems is great. I won't bore you with the details on how to take the extruder apart. The Makerbot replicator extruder has a complex order in the way it has to be disassembled. During disassembly I discovered little things that I could improve during assembly to improve reliability. And possibly increase the longevity of the extruder. Because I had the extruder apart I took the opportunity to replace the ceramic insulation on the heater block before assembly. Assembling the extruder the right way! In a way it's very easy. You just need to know the trick. Start with the nozzle and the heater block and then add all extruder parts where the filament goes through mate with each other.

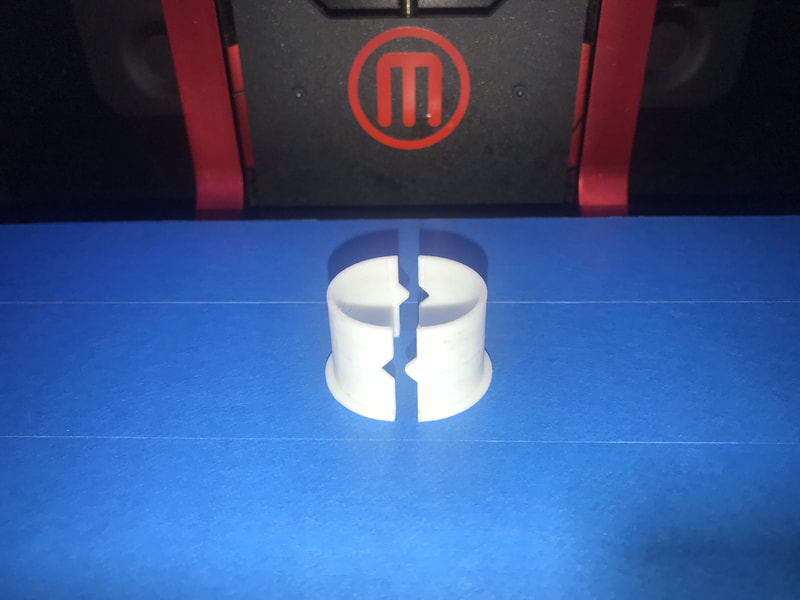

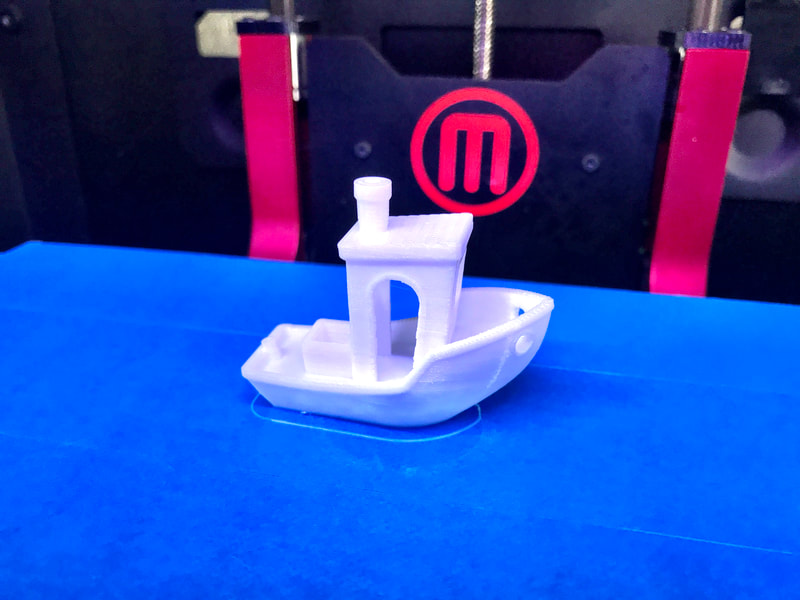

I quickly whipped up something I wanted to print and used it to test the printer. It printer beautifully on the first print. And off course you must then print a Benchy boat to see how it performs. Which I am very impressed with too. The parts below were printed in white PLA. The slice the first part I quickly used Makerbot print. The slicer made by Makerbot for Makerbots. Benchy boat was sliced using the latest version of Simplify3d. Expect more updates around 3D printing in the near future. And I will be adding a lot more content to my dedicated 3D printing page.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorGeorge Timmermans, Research Toolmaker, Software Engineer and Tinkerer Archives

March 2024

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed