|

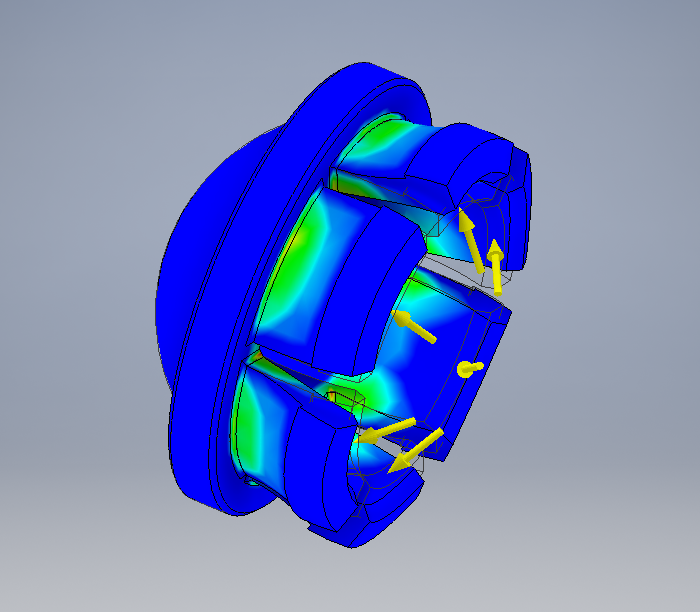

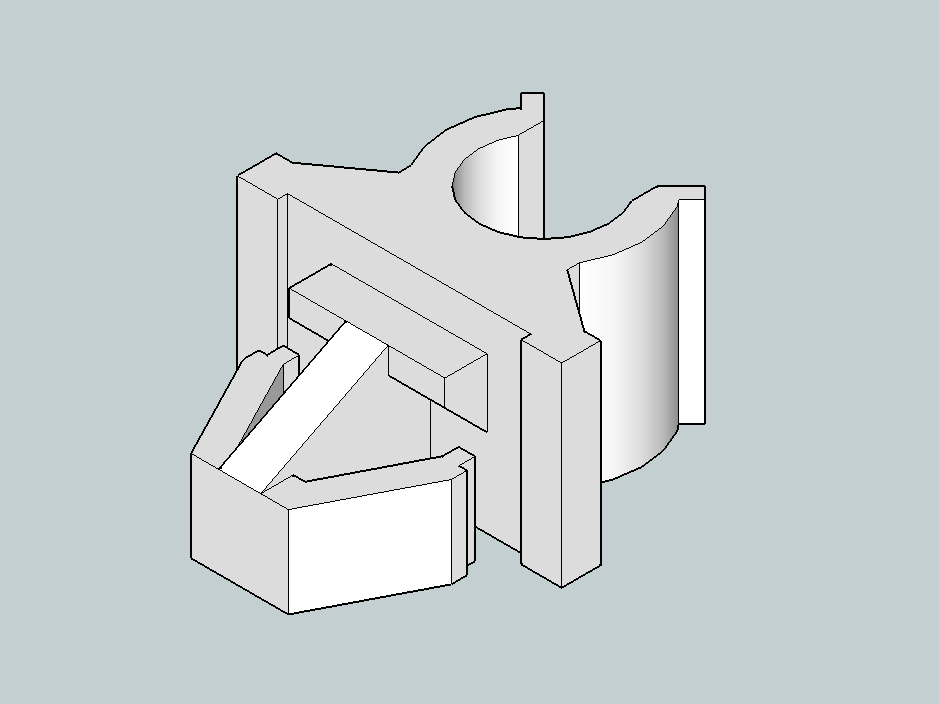

I decided it was about time to see if I could repair a pop up headlight for a 1990 Mazda Eunos Roadster (Miata). The part in question is a plastic part that had worn out and causes a wobbly headlight. The Genuine Mazda Part Number is: NA01-51-SA5 but consist out of parts I don't really need to replace. The cost of the replacement part is around 25 NZD + 25 NZD shipping. I took the damaged part from the car, measured the critical dimensions and created a CAD model in Autodesk Inventor Pro 2016 that I recently acquired with a three year license. I found this website with the necessary coefficients to add PLA to the material database. PLA is the main material I use for 3D printing. The part clips over a ball joint so I use the stress analysis in Inventor to see how it would behave. See picture below. Unfortunately it doesn't reflect the weakness between layers created by Fused Deposition Modeling (FDM) used by my 3D printer. I tried a couple of iterations but every time I tried to snap the newly printed part on the ball joint some of the clips would break off. I wish I had some Nylon filament to try out. Nylon is used for 3D printing very strong parts and has great strength between layers. In the end I decided to order a genuine replacement part. I prefer not to have the headlight close on me while driving at night. Other PartsBelow is a picture of a clip I designed in SketchUp over a year ago. It is a replacement for the clip that holds the rod that you use to keep the hood of the car up while doing maintenance in the engine bay. I know it seems pretty insignificant but I am surprised it is still holding up to temperatures and vibrations within the engine bay. Yuo can download the source file and 3D print file here. Another part that resulted in a failure was a plastic part that connected to drivers-side suns visor to the car. The original had broken in two halves and i looked like a previous owner of the car might had taken it apart and had made matters worse. A working is important for the Warrant Of Fitness for the car. Again I took the critical dimensions and made a simple replacement for testing. It looked promising to start of with until a very nice summers day. The car is a racing green colour with a black soft top. The temperature of the body of the car and inside of the car had risen to such an extend that the PLA had become a little soft and the weight of the sun visor deformed it. I repaired the original with a composite glue but if it breaks again I might try printing it in ABS. UpdateI sold the car in 2018 with the clip I 3d printed in PLA in 2015 in it! So depending on what it is and where it is installed it is possible. A lot off better materials are on the market today for 3d printing.

2 Comments

|

AuthorGeorge Timmermans, Research Toolmaker, Software Engineer and Tinkerer Archives

March 2024

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed