|

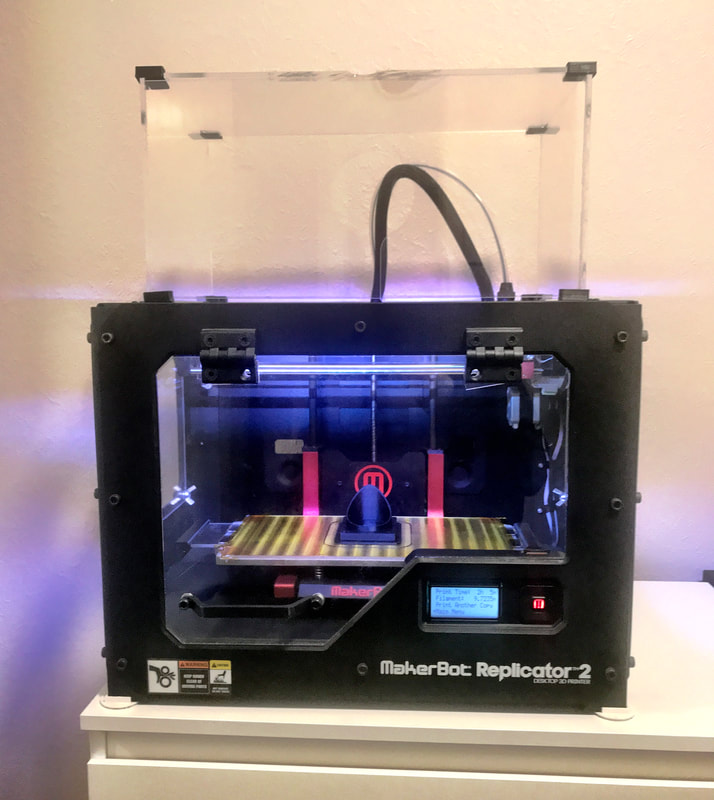

Now I'm back into 3D printing one of my curiosities is in printing with different materials. The stock Makerbot Replicator 2 as designed for printing PLA only. Many of the upgrades I added to the printer where to be be able to print different materials. Why? Different materials have different strengths and weaknesses and are therefore better or worse for particular applications. I like t have the option to pick the best material for a particular part depending on what it will be used for. For example my action camera mount for on your dashboard when printed in PLA suffers from warping when your dashboard heats up in the sun. That is because the glass transition temperature for PLA is between 60-65 °C. A common plastic used for 3d Printing is ABS. ABS has a glass transition temperature ~105 °C. Glass transition temperature is not the only property to look for. Depending on what you are printing you might care about some of the following:

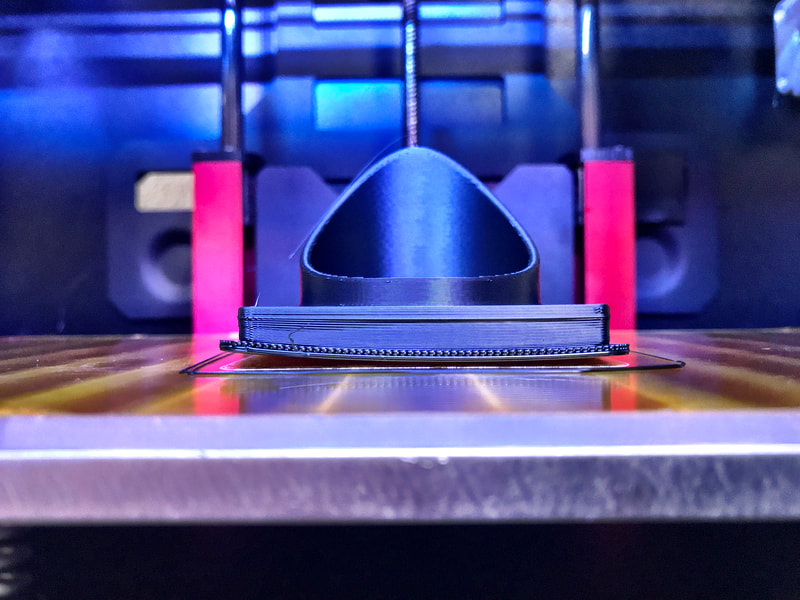

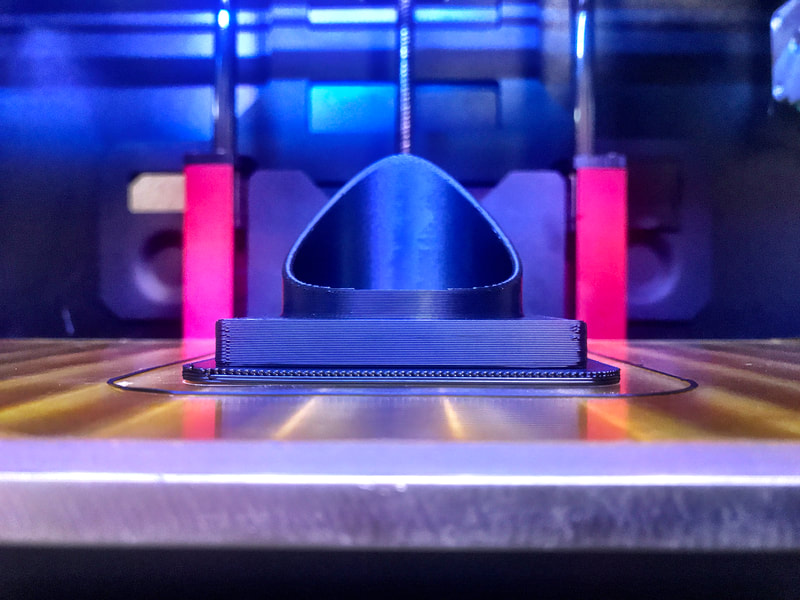

Printing ABSFirst attempt settings that required changing later:

First attempt settings that required changing later:

I'm excited to try new materials in the future. For more information on my Simplify3d configuration for a Makerbot Replicator 2 with Heated Build Platform (HBP) see Simplify3d Configuration.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorGeorge Timmermans, Research Toolmaker, Software Engineer and Tinkerer Archives

March 2024

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed